120 Feet Road, Jalandhar, Punjab

- GST NO. : 03AHJPA8461B1ZV

Speciality Chemicals

Leading Manufacturers and Wholesaler of Leather Finishing Chemicals, Paint Enhancing Chemicals, Rubber Sheet Chemicals, Construction & Waterproofing Chemicals and Liquid Tile Adhesive Technology Products from Jalandhar.

MOQ : 100 Litre

| Business Type | Supplier |

| Form | Liquid |

| Application | Industrial |

| Purity | 100% |

| Packaging Type | Bottle |

| Appearance | Transparent |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

Leather is one of the most widely traded commodities globally since ancient times. The growth in demand for leather is driven by the footwear. The leather industry has a place of prominence in the Indian economy due to substantial export earnings and growth. The Indian leather industry accounts for around 13 per cent of the world’s leather production of hides/skins.

India is the 5th largest exporter of Leather goods and accessories in the World with a massive share of around 25% in the country’s export of Leather & Leather Products.

Indian Leather Industry serves as an essentially commodity for :

- Garment Industry

- Fashion, Bags, and accessories

- Handicrafts

- Footwear

- Military equipment

- Sports Equipment

- Automotive

- Architectural and Interior Designing

MOQ : 100 Bottle

| Business Type | Supplier |

| Usage | Paint Industry |

| Country of Origin | India |

| Grade | Technical Grade |

| Form | Thick Liquid |

| Features | Safe to use, Balanced composition, Stability |

| Purity | 99 % |

Preferred Buyer From

| Location | Anywhere in India |

Primebind :

- Improves Shine, Strength and Bonding

- An Additive for Primer, Distemper, Rustic, Limestone, Samosam

- s Increases Coverage and life

MOQ : 100 Litre

| Business Type | Supplier |

| Packaging Type | Bottle, Barrel |

| Application | Rubber Sheets, Industrial |

| Purity | 99% |

| Country of Origin | India |

| Form | Liquid |

| Moisture | 0-5% |

Preferred Buyer From

| Location | Anywhere in India |

Rubber is one of the most versatile material, and it is used in manufacturing of Rubber Slippers, anti-vibration mountings, protective gears, sports equipment, shock absorptions, seals, mattresses, automotive components, Rubber Sheets for designer bags and accessories, mattresses, and architectural needs.

We manufacture specialized chemicals products for rubber sheet production used in manufacturing of designer bags, wallets, slippers, and other fashion accessories.

- COI® BINDER PS : Medium soft acrylic high solid emulsion impart good adhesion, high covering with optimised tack with high flexibility and fastness properties.

- COI® BINDER RS : Medium soft acrylic emulsion impart adhesion, good covering, very good tack with high flexibility and fastness properties.

- COI® PIGMENTS CASEIN FREE* : Colour Emulsion having Fine particle colour size with high covering power, no tack, and uniform coating formation

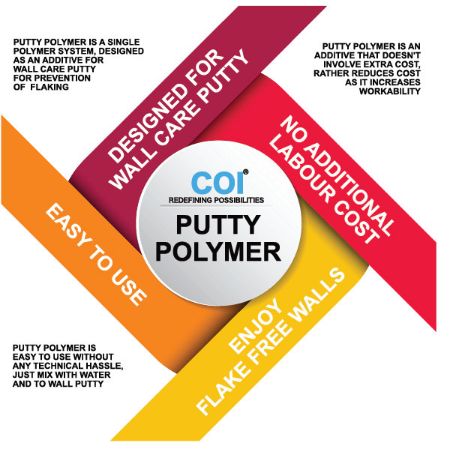

MOQ : 100 Bottle

| Business Type | Supplier |

| Material | Polymers |

| Form | Liquid |

| Application | Manufacturing Units, Textile Use |

| Purity | 90% |

| Packaging Type | Bottle |

| Packaging Size | 400gm |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

Putty Polymer is an additive for Dry Wall Putty, which consists of high-performance Polymer, that improves the quality, mechanical properties, and durability of Wall Putty.

Advantages :

- It imparts strength and flexibility

- Improves workability and smoothness

- Prevents Flaking due to Salt Petre

MOQ : 100 Bottle

| Business Type | Supplier |

| Form | Liquid |

| Application | Additive Polymer for Premix Dry Tile Adhesive for Better Bonding |

| Feature | Antistatic, Heat Resistant, Waterproof |

| Type | Liquid Tile Adhesive |

| Advantage | Waterproof |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

Cement has been the main ingredient in the construction industry. The traditional method of laying tiles, marbles, or stonewares is to fix them using cement mortar. Often the tiles have been seen falling when the bonding between the tile and substrate weakens.

The Construction Industry asked for a different method that could increase the adhesive significantly to avoid such failures to happen. In 1950s, Liquid Polymer Technology was introduced, and it opens up new segment of Tile Adhesives.

However, Liquid Polymer Tile Adhesive Technology being one of practical, economical, and the best method, yet construction industry couldn’t exploit the potential of this technology.

Generally, tiles are being laid by mixing cement and sand in ratio of 1:3 to 1:6. Powdered Adhesive is one such example. It consists of cement, sand and polymer, with their ratio depends upon the quality and cost, and used as a Tile Adhesive.

We developed and introduced Liquid Tile Adhesive Technology to enable construction industry to re-explore, and reap the benefits of this technology.